Hazardous materials need to be packaged and closed properly to prevent the possibility of a spill or leakage during transportation. Shippers are required to follow the manufacturer’s closure instructions while packaging hazardous materials. Failing to follow these instructions can significantly increase the risk of a hazmat incident – the consequences of which can be quite serious.

Why Is It Important to Follow the Manufacturer’s Closure Notification?

Section 173.22 of 49 CFR states that hazmat shippers need to follow the manufacturer’s closure instructions to make sure the integrity and effectiveness of the packages are not compromised during transportation. These instructions tend to be extremely detailed and tell you exactly what you need to do in order to close hazmat packages safely. These might include:

- What kind of packaging components you need

- Torque specifications to be followed while sealing the container

- What kind of tape you need to use

- How many strips of tape you need to use and how it must be applied

- How the inner packaging must be closed

- How you should put the package together

- Whether the container with hazardous materials should be placed upright in the package

- How to properly seal the outer package

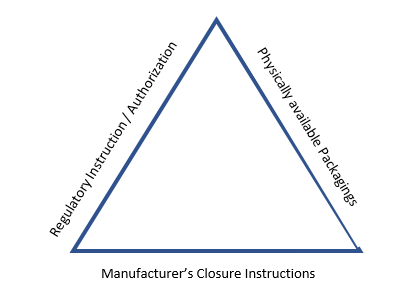

The manufacturer’s closing instructions are a part of what is called the packaging triangle for hazardous material transportation. The other two legs of the triangle represent the regulatory requirements for packaging and the physical packaging components respectively.

Responsibilities of Hazmat Shippers

- Each instruction provided by the manufacturer or subsequent distributor must be followed precisely. You are not allowed to modify the instructions under any circumstances.

- You should keep a copy of the closing instructions for a period of 90 days – starting from the date on which the packages are offered to the carrier. In case of an inspection by a DOT representative, you need to provide them with all the relevant documents – including the copy of the closing instructions. With that said, if the instructions are permanently embossed or printed on the package itself, you are not required to keep a copy of the instructions on file.

- In case you do not receive the required instructions, you must contact the manufacturer or the distributor immediately and ask them for the relevant instructions and supporting documentation. This type of documentation or instructions can help in adhering to the mandatory hazmat regulations.

- Click here for an example of a closure instruction.

It should be noted that shippers are not allowed to use substitutes instead of the originally recommended packaging materials or components. Doing so can not only compromise the integrity of the package, as a result of which it might fail to perform to its rated capacity, which in turn can increase the risk of a hazmat incident significantly.

The only exception is the packaging tape, which can be substituted if needed – as long as the substitute tape meets the necessary safety standards. In May 2022, the Pipeline and Hazardous Materials Safety Administration (PHMSA) issued a notice of enforcement discretion regarding the use of tape while packaging and closing hazardous material packages.

The notice states that shippers are allowed to use a different packaging tape than what was recommended by the manufacturer or the distributor – as long as the use of a different tape does not compromise the integrity of the packages or violates the Code of Federal Regulations in any way.

According to the notice issued by the PHMSA, the substitute tape in question meets the following criteria.

- It should be made of the same material or a similar material as the originally recommended tape.

- It should be equal to or better than the originally recommended tape in terms of width, length, thickness, ductility, and adhesive properties.

- It should be compatible with the packaging.

It is important to note that this notice is meant to provide temporary relief to shippers who are struggling to meet the regulatory requirements for packaging – due to the global supply chain crisis caused by the COVID-19 pandemic. It is only effective until August 31st, 2022.

Allow Us to Review

Now that there is a general understanding of what a closure instruction is, let’s talk details. A manufacturer’s closure instruction provides the step by step instructions for how fill and build a package of hazmat / DG for shipment. These instructions are designed to clearly indicate the filling limit on a package as well.

This begs the question – Just how specific are they? To simplify things, we will look at a combination package of a 4G box with a 1-gallon paint can style inner. On a well-written set of instructions, there will be the following pieces of information.

• A list or description of al the packagings pieces and parts

• Pictures of all the packagings and how they should properly fit together in a step-by-step manner.

• UN Performance Packaging Code – this tells a shipper exactly which packing groups are allowed as well as the maximum gross weight for the final package. Examples of codes for this package could be UN 4G / Y 8.3 / S or UN 4G / Y 7.1 / S

• Instructions for how to apply any lids. Terminology here could include “using a paint can closer” or “center the friction plugs” along with how to attach the locking rings.

• Specifics for exactly which type and size of tape to use such as “3M #375 48 mm clear tape” or “3M-375, poly (BOPP) PST, 48 mm minimum width”

• Assembly instructions for how to build the outer box using wording such as “fold in bottom flaps and seal center seam” or “close the bottom minor than major (outside) flaps of box”. There will also be information for how to close and seal the final package.

• Specifics for how to place the loaded inner container inside the outer. Here the phrases “place can/ring assembly in an upright position in the box” or “place the properly closed inner packaging into the box”.

That is a lot of information to process! Keep in mind these closures instructions are written to ensure a package filled with a hazardous material or dangerous good will not leak, rupture, or spill during the course of normal transit. Should a shipper not follow the instructions or use “substitute components” there is no guarantee from the packaging manufacturer that those types of incidents will not occur.

Keep in mind that if a company ships hazardous materials under the 49CFR regulations, it is required to keep these instructions on file for” at least 90 days once the package is offered to the initial carrier for transportation in commerce”.

So, what is the bottom line? To be compliant with the regulations and to keep everyone safe, follow the manufacturer’s closure instructions to the letter. If a question arises, call the manufacturer for clarification.

Consequences of Failing to Follow the Closure Instructions

Failing to follow the closing instructions provided by the manufacturer is a violation of federal law and can lead to civil penalties. The penalty for failing to close a hazmat package in accordance with the manufacturer’s instructions is $4,500. It’s salient to note that this is only a baseline assessment and the amount of penalty to be paid can be considerably higher – depending on the severity of the violation.

The amount of penalty you might have to pay depends on several factors including:

- The circumstances under which the violation happened

- The severity of the violation

- Whether your violation caused a hazmat incident and whether it resulted in property damage, injuries, or deaths

- To what extent you were responsible for the violation

- Whether you have violated federal regulations before

- Whether paying the penalty might affect your ability to continue in business in any way

It’s crucial to note that if your violation of a regulation or safety permit results in a hazmat incident in which one or more people are injured or killed, and if it is found that you knowingly or recklessly violated the regulation, you could face a prison sentence of 5 years.

Need to Learn More about Hazmat Closure Instructions? Hazmat University Can Help You

Transporting hazardous materials is risky in every sense of the word. At each and every step of the process, there are regulations to be complied with and instructions to be followed in order to mitigate the risks involved. If you are involved in hazmat transportation in any capacity, it is critically important for you to be aware of these regulatory requirements.

At Hazmat University, we offer comprehensive online training programs for people who are involved in the business of hazmat transportation. Our training programs are designed to educate you on all the relevant regulatory requirements and to help you gain a functional knowledge of the measures that need to be taken to transport hazardous material packages safely. Contact us today to learn more!

Be Confident. Be Competent. Be Compliant.